Equipment

The nanoGUNE facilities are managed by specialists and used by researchers from a wide variety of fields.

NanoGUNE's External-Services department offers a wide range of characterization and fabrication services to external users, both academic and industrial.

NanoGUNE's equipment is presented below.

-

Ion Beam Etcher (4Wave)

Ion Beam Etcher (4Wave) -

Quantum Design SQUID-VSM EverCool

Quantum Design SQUID-VSM EverCool -

E-Beam and thermal evaporation - Lesker

E-Beam and thermal evaporation - Lesker -

ALD Cambridge Nanotech Savannah S100

-

Leica EM MED020 / Quorum technologies Q150 T ES

Leica EM MED020 / Quorum technologies Q150 T ES -

Electron-Beam Lithography (Raith -150-TWO / E-line)

Electron-Beam Lithography (Raith -150-TWO / E-line) -

Dual-beam FIB/SEM (Focused Ion Beam and Induced deposition)

Dual-beam FIB/SEM (Focused Ion Beam and Induced deposition) -

X-ray reflectivity/diffractometry (Malvern - PANalytical)

X-ray reflectivity/diffractometry (Malvern - PANalytical) -

Quantum Design PPMS

Quantum Design PPMS -

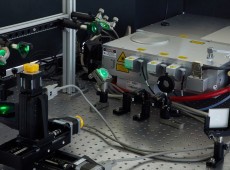

Magneto-Optical Kerr Effect (MOKE) set-up

Magneto-Optical Kerr Effect (MOKE) set-up -

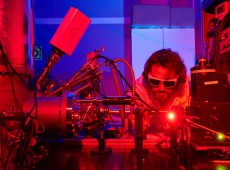

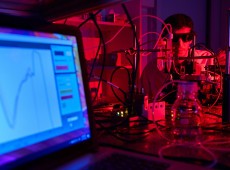

Magneto-Optical Kerr Effect (MOKE) microscope

Magneto-Optical Kerr Effect (MOKE) microscope -

UHV Sputtering System (AJA Int.)

UHV Sputtering System (AJA Int.) -

Electrospinning

Electrospinning -

Reactive ion etcher (RIE Oxford Plasmalab 80 Plus)

Reactive ion etcher (RIE Oxford Plasmalab 80 Plus) -

Spectroscopic ellipsometrer (GES5 spectroscopic-ellipsometer SEMILAB)

Spectroscopic ellipsometrer (GES5 spectroscopic-ellipsometer SEMILAB) -

RAMGRABER Wet benches

RAMGRABER Wet benches -

Double Pack Oven, 650ºC UNITEMP RSO-650-200

Double Pack Oven, 650ºC UNITEMP RSO-650-200 -

ALD Beneq TFS 200

ALD Beneq TFS 200 -

Mask aligner (EVG)

Mask aligner (EVG) -

FTIR Spectrometer PerkinElmer Frontier

FTIR Spectrometer PerkinElmer Frontier -

Environmental Scanning-electron Microscope (eSEM-FEI Quanta 250)

Environmental Scanning-electron Microscope (eSEM-FEI Quanta 250) -

High power industrial Picosecond Laser

High power industrial Picosecond Laser -

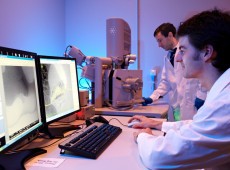

High-resolution Transmission Electron Microscope (HRTEM)

High-resolution Transmission Electron Microscope (HRTEM) -

Four point probe

Four point probe -

STM/AFM (4 K) in UHV with light detection set-up

STM/AFM (4 K) in UHV with light detection set-up -

STM/AFM (1 K) in UHV with magnetic field

STM/AFM (1 K) in UHV with magnetic field -

UV-NIR Spectrometry

UV-NIR Spectrometry -

3D Optical Profiler

3D Optical Profiler -

Surface Plasmon Resonance Platform

Surface Plasmon Resonance Platform -

NIR Raman spectroscopy

NIR Raman spectroscopy -

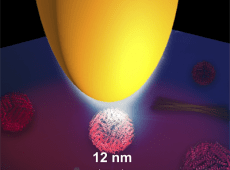

High Resolution Atomic-Force Microscopy

-

FTIR Spectrometer PerkinElmer Frontier

FTIR Spectrometer PerkinElmer Frontier -

Scattering-type near-field microscope (NeaSpec)

Scattering-type near-field microscope (NeaSpec) -

Plasma asher

Plasma asher -

Microscopy Platform for Materials Research

Microscopy Platform for Materials Research -

Scattering-type near-field microscope (Neaspec)

Scattering-type near-field microscope (Neaspec) -

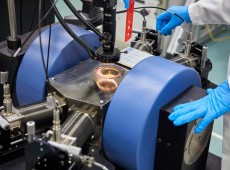

CRYO Plasma FIB

CRYO Plasma FIB -

Direct Laser Writer

Direct Laser Writer

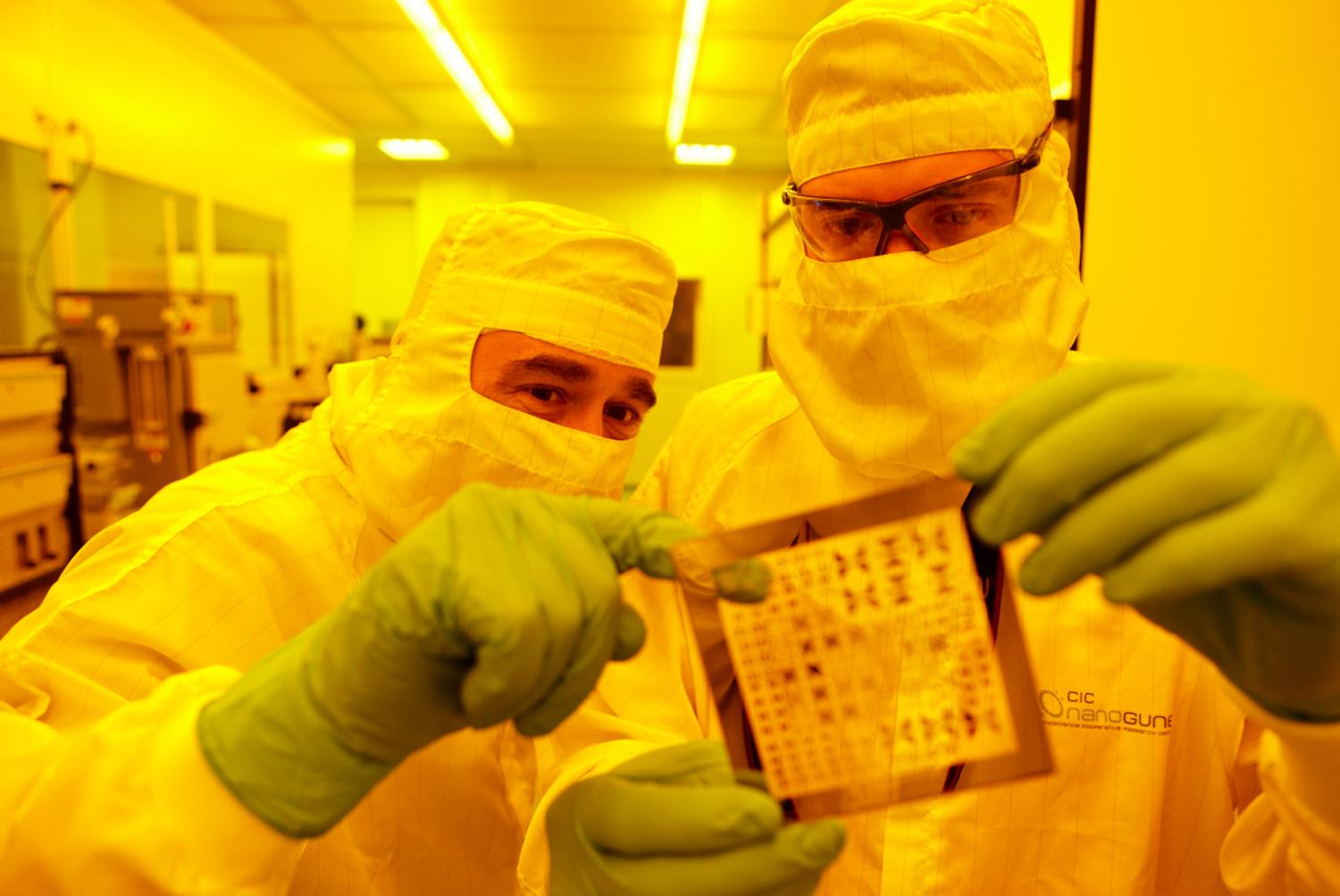

Cleanroom

The nanoGUNE cleanroom, dedicated to fabricate and characterize the properties of materials on the nanoscale, ia a 300m2 laboratory where the air purity is under strict supervision.

Facilities & Equipment

A unique infrastructure of 6 200 m2 was set up to host a cleanroom of nearly 300m2 and 15 ultra-sensitive laboratories with state-of-the-art equipment.